Clean Room Design

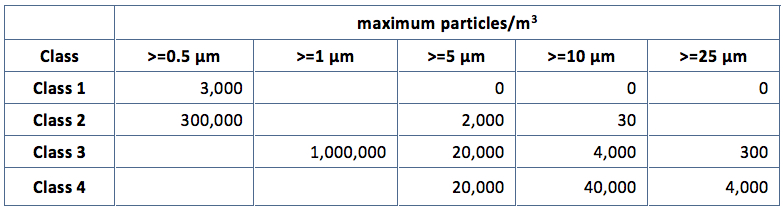

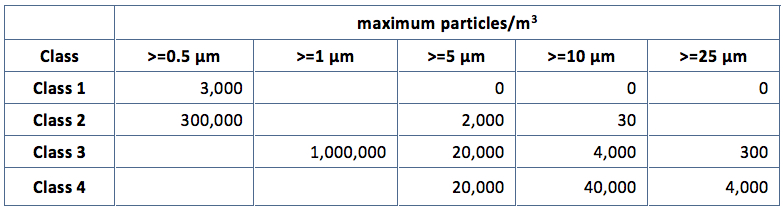

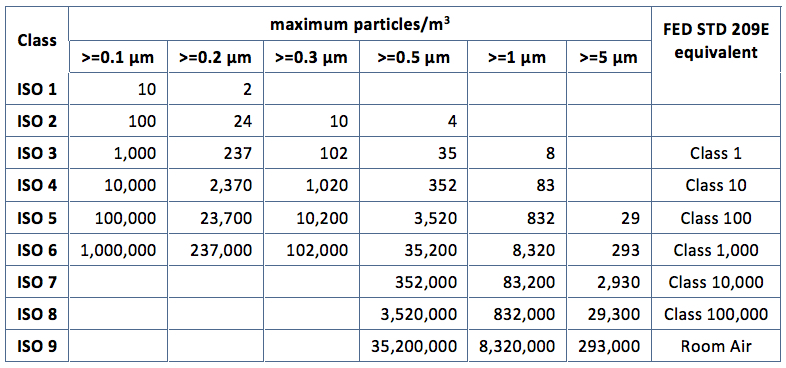

- Designing of clean room from ISO class 1 to ISO class 9 (FS209E class 100 to class 1, 00,000)

- Designing of modular partition, Walkable / non-Walk able ceiling, doors, windows, clean room light fittings.

- Checking and Inspection of Epoxy, coving / L- Flashing, Silicon filling.

- Preparation of specification for clean room modular partition, BOQ (Bill of Quantity), tender documents.

Cleanroom design concepts

Contamination control is the primary consideration in cleanroom design; however, the relationships between contamination control and airflow are not always well understood.

As a first step towards design and construction of the cleanroom and air handling systems, a basic specification must be developed. For this the following factors must be accounted for:

- Defining the area of the clean space

Establishing the correct cleanliness level (in relation to the international cleanroom standards)

Establishing the optimal air change rate and determination of the supply airflow rate. (There should be not less than 20 hourly air changes in the controlled area.) - Establishing requirements for positive pressure differentials (normally 10-15 Pascals between adjacent cleanrooms). This range allows doors to be opened and overcomes problems for cleanroom operators in relation to the high pressure difference, which arises due to air leakage.

- Considering use of mini-environments for additional air cleanliness (such as localized unidirectional airflow or isolators)

- Optimizing ceiling coverage in relation to air filters. With HEPA filters, the design should seek to include: HEPA filters with differential pressures (P); adequate space for low pressure drop air flow; low face velocity; fan design; motor efficiency; variable speed fans

- Minimizing the pressure drop (air flow resistance)

- Adequate sizing and minimizing the length of ductwork

- Optimizing pressurization

- Reducing air flow when the cleanroom is unoccupied (to save energy consumption)

- Efficient use of components

- Defining the electrical systems that power air systems

With cleanrooms used in the pharmaceutical industry, there are additional considerations aimed at minimizing contamination. These are centered on the idea that cleanrooms should be constructed in a way which makes them easy to clean and disinfect. It’s important that such cleanrooms have:

- A smooth and cleanable finish

- A final coating which is impervious to detergents and disinfectants

- No uncleanable recesses

- Very few projecting ledges

- Very few electrical sockets

- Pipes and conduits are appropriately boxed in

Pressurization

Temperature Control

Humidity Control

acility Layout

Airlocks or AnteRoom

Windows

Pass-Throughs

Siting

Materials for Cleanroom Design & Construction

Walls

Wall Finishes

Doors

Ceilings

Floors

Air Conditioning (HVAC) & Filtration Systems

Airside

Filtration

Filter Location

Cleanroom Overview

Cleanrooms are used in practically every industry where small particles can adversely affect the manufacturing process. They vary in size and complexity, and are used extensively in industries such as semiconductor manufacturing, pharmaceuticals, biotech, medical device and life sciences, as well as critical process manufacturing common in aerospace, optics, military and Department of Energy.

A cleanroom is any given contained space where provisions are made to reduce particulate contamination and control other environmental parameters such as temperature, humidity and pressure. The key component is the High Efficiency Particulate Air (HEPA) filter that is used to trap particles that are 0.3 micron and larger in size. All of the air delivered to a cleanroom passes through HEPA filters, and in some cases where stringent cleanliness performance is necessary, Ultra Low Particulate Air (ULPA) filters are used.

Personnel selected to work in cleanrooms undergo extensive training in contamination control theory. They enter and exit the cleanroom through airlocks, air showers and/or gowning rooms, and they must wear special clothing designed to trap contaminants that are naturally generated by skin and the body.

Depending on the room classification or function, personnel gowning may be as limited as lab coats and hairnets, or as extensive as fully enveloped in multiple layered bunny suits with self contained breathing apparatus.

Cleanroom clothing is used to prevent substances from being released off the wearer’s body and contaminating the environment. The cleanroom clothing itself must not release particles or fibers to prevent contamination of the environment by personnel. This type of personnel contamination can degrade product performance in the semiconductor and pharmaceutical industries and it can cause cross-infection between medical staff and patients in the healthcare industry for example.

Cleanroom garments include boots, shoes, aprons, beard covers, bouffant caps, coveralls, face masks, frocks/lab coats, gowns, glove and finger cots, hairnets, hoods, sleeves and shoe covers. The type of cleanroom garments used should reflect the cleanroom and product specifications. Low-level cleanrooms may only require special shoes having completely smooth soles that do not track in dust or dirt. However, shoe bottoms must not create slipping hazards since safety always takes precedence. A cleanroom suit is usually required for entering a cleanroom. Class 10,000 cleanrooms may use simple smocks, head covers, and booties. For Class 10 cleanrooms, careful gown wearing procedures with a zipped cover all, boots, gloves and complete respirator enclosure are required.

Cleanroom Air Flow Principles

Cleanrooms maintain particulate-free air through the use of either HEPA or ULPA filters employing laminar or turbulent air flow principles. Laminar, or unidirectional, air flow systems direct filtered air downward in a constant stream. Laminar air flow systems are typically employed across 100% of the ceiling to maintain constant, unidirectional flow. Laminar flow criteria is generally stated in portable work stations (LF hoods), and is mandated in ISO-1 through ISO-4 classified cleanrooms.

Proper cleanroom design encompasses the entire air distribution system, including provisions for adequate, downstream air returns. In vertical flow rooms, this means the use of low wall air returns around the perimeter of the zone. In horizontal flow applications, it requires the use of air returns at the downstream boundary of the process. The use of ceiling mounted air returns is contradictory to proper cleanroom system design.

Cleanroom Classifications

Cleanrooms are classified according to the number and size of particles permitted per volume of air. Large numbers like “class 100” or “class 1000” refer to FED_STD-209E, and denote the number of particles of size 0.5 mm or larger permitted per cubic foot of air. The standard also allows interpolation, so it is possible to describe e.g. “class 2000.”

ISO 14644-1 Cleanroom Standards

BS 5295 Cleanroom Standards